Refrigeration and Air Conditioning Compound

10% + Energy Savings on AC / Refrigeration

Reduced Maintenance

Longer Equipment Life

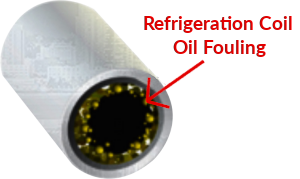

MaxR is a non‐invasive synthetic refrigerant compound. MaxR100 removes migrated oil that fouls the heat transfer in the coil tubes.

MaxR chemically bonds with the metal surfaces of the compressor and refrigeration tubes causing the release of accumulated oil. This chemical bond causes zero surface tension on the metal surfaces reducing friction and preventing future oil accumulation.

MaxR reconditions, restores and maintains refrigeration system efficiency by improving the heat transfer coefficient in the condenser and evaporator coils. MaxR allows the system to operate at or near original specification, reducing equipment wear and extending HVAC unit service life.

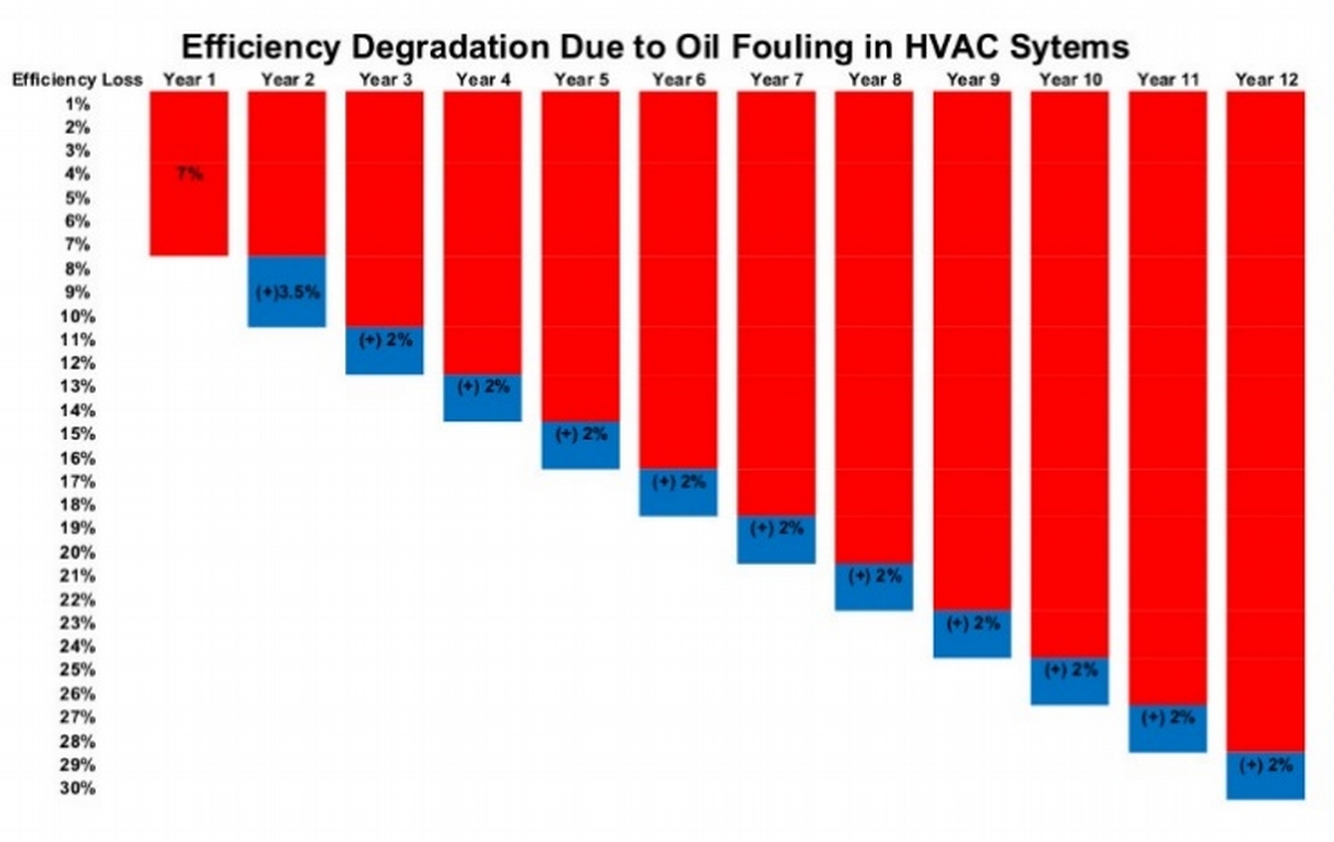

Eliminating Oil Fouling Results in a 10% - 25% energy savings.

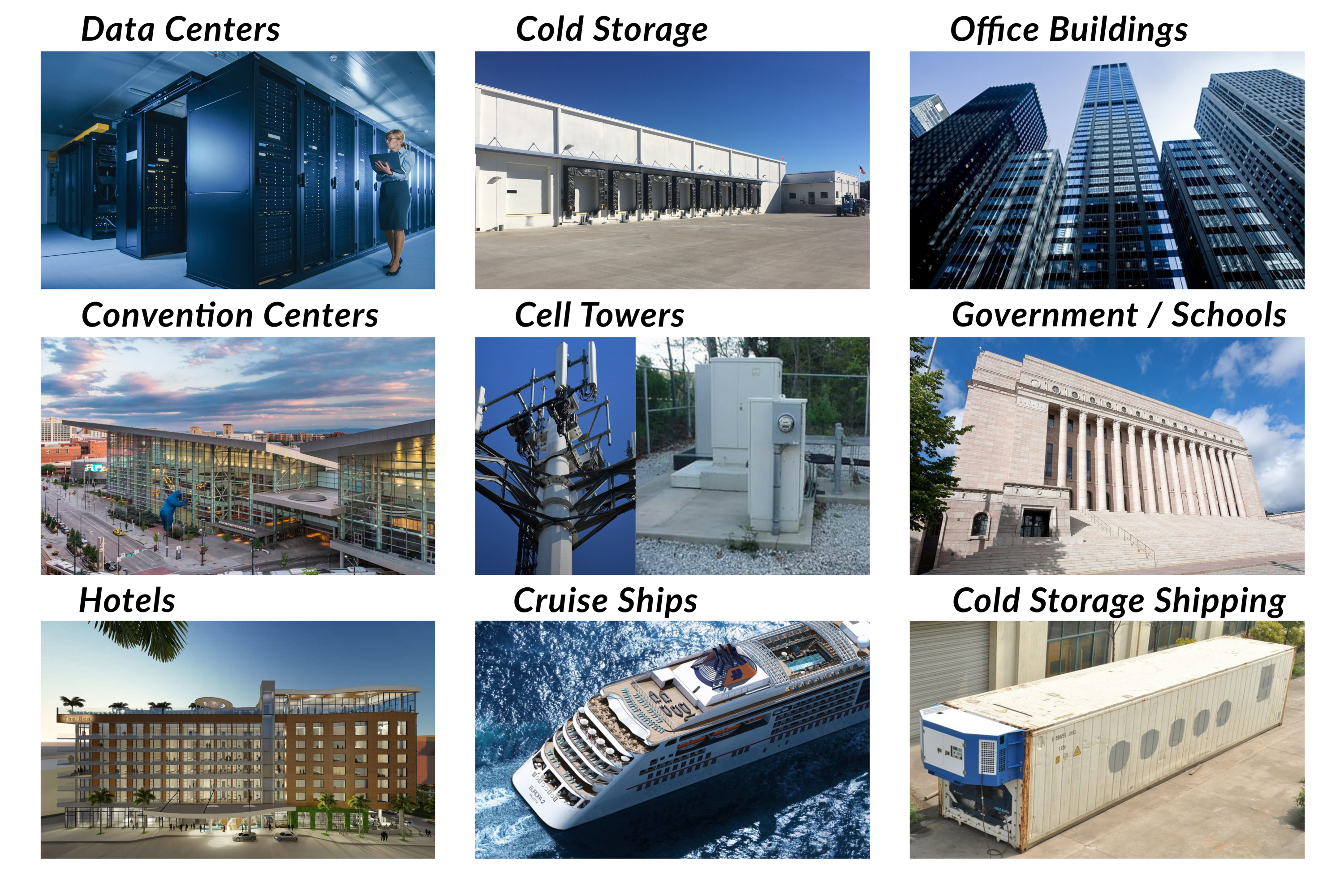

MaxR Improves Performance in:

MaxR is Safe for Equipment

MaxR is free of Halogen group elements: Chlorine, Fluorine, Sulphur of Phosphorous and PTEF.

Intertek Group plc performed the ASHRAE 97 test referenced in Section 7 of SAE J2670 Issue: 2011/02/01 Stability and Compatibility Criteria for Additive and Flushing Materials Intended for Aftermarket Use in R-134a (HFC-134A) and R-1234yf (HF0-1234yf) Vehicle Air-Conditioning Systems on MaxR.

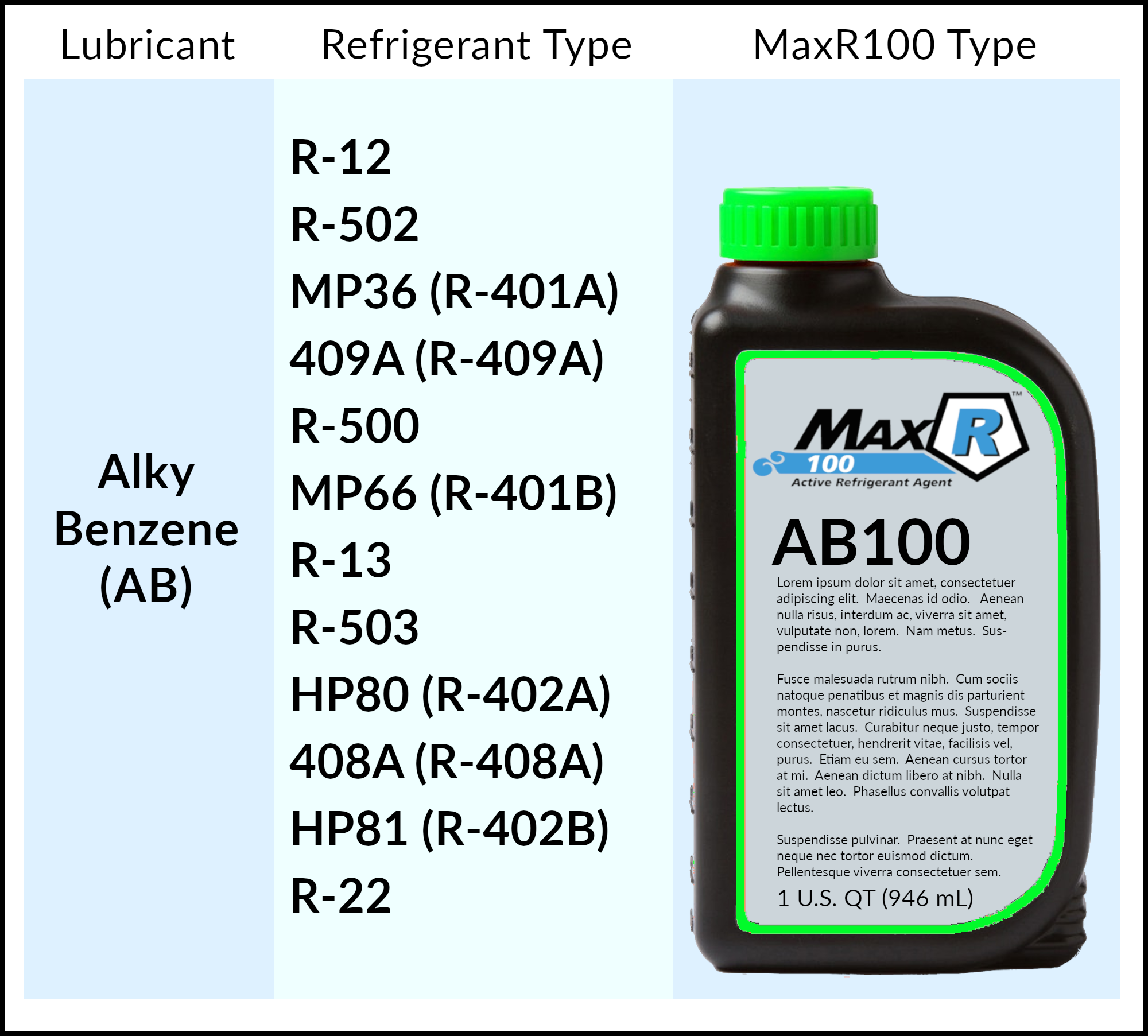

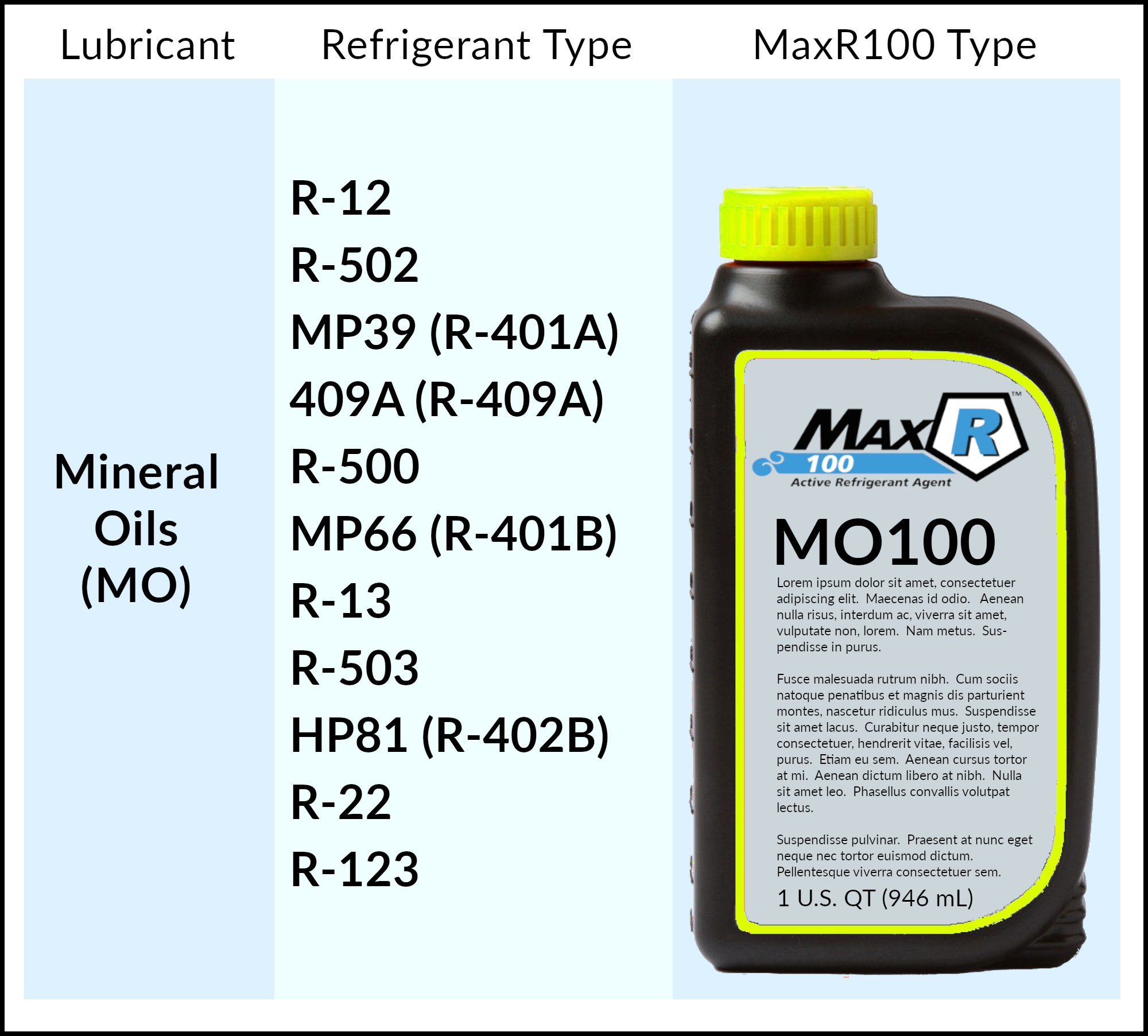

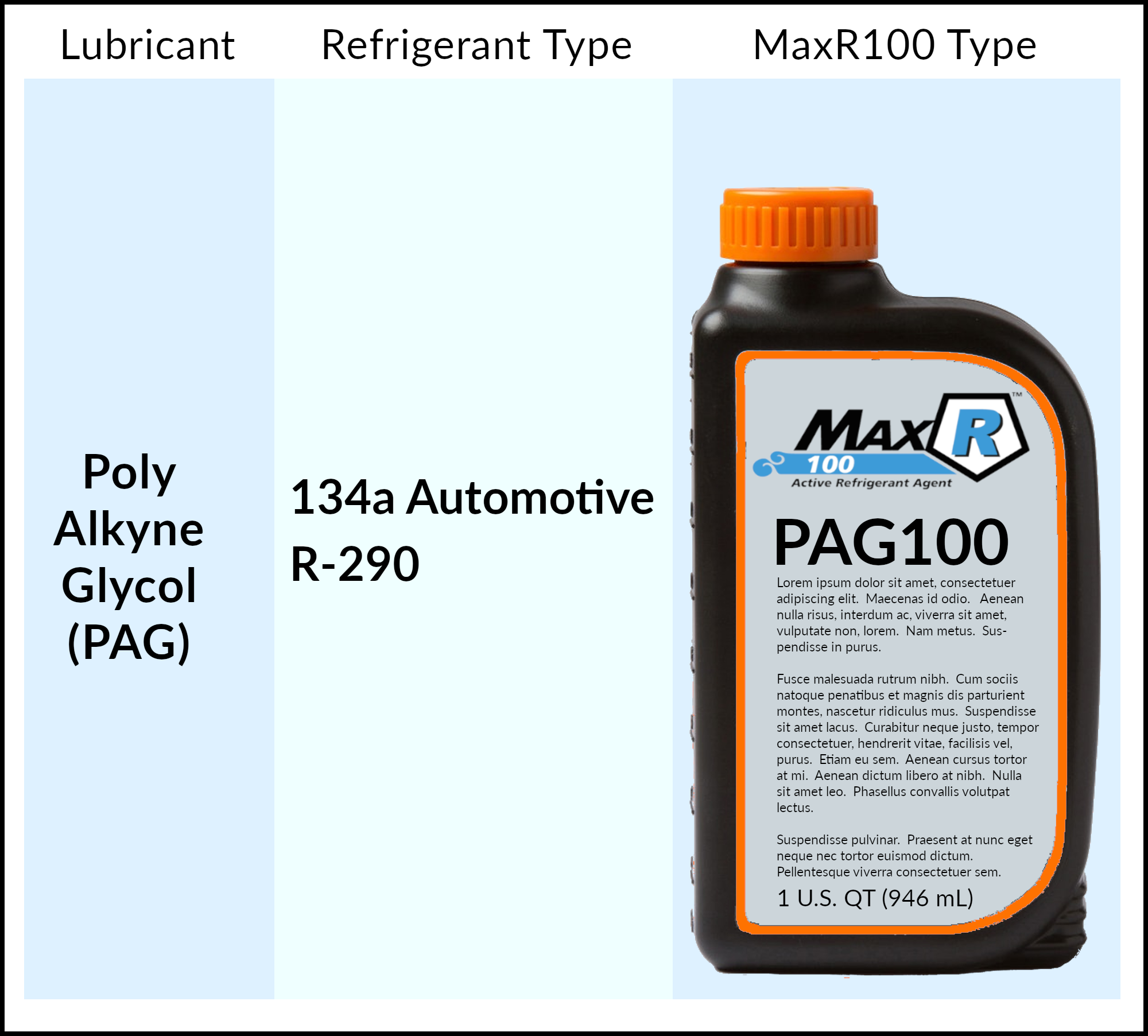

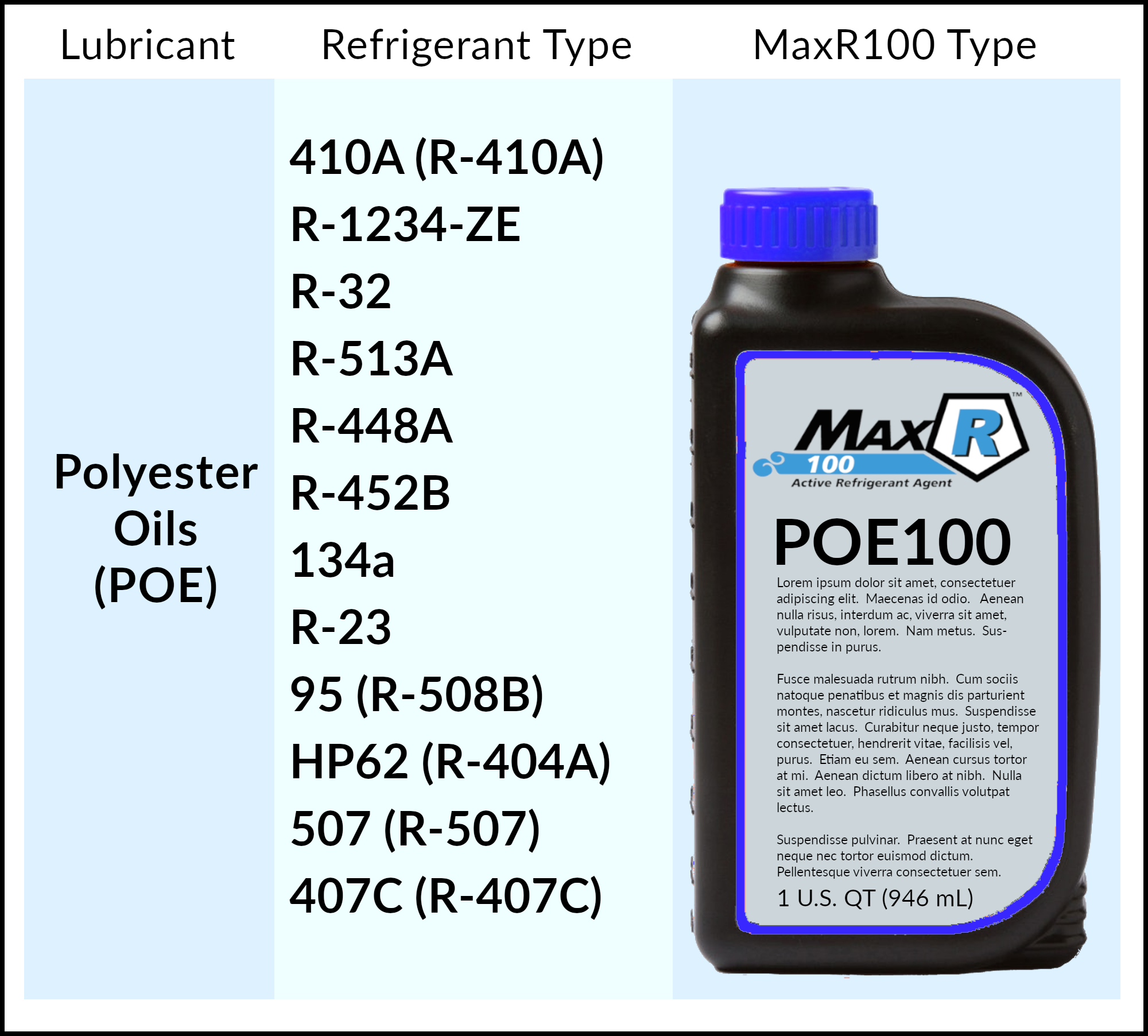

Conclusion: MaxR met the acceptance criteria and chemical compatibility for refrigerant applications compatible with all types of refrigerant oils: Mineral Oils (MO), Polyester Oils (POE), Alky benzene (AB) and Poly alkyne Glycol (PAG).

MaxR a ONE-TIME application

for the life of the air conditioning or refrigeration systems.

The Problem — Oil Fouling

ASHRAE reports in normal use, 5% - 8% of compressor lubrication oil mixes into the refrigerant. This oil accumulates on the inner walls of evaporative and condensing coils, insulating them and reducing heat transfer efficiency.

Average efficiency loss is:

Year 1 - 7%

Year 2 - 3.5%

Year 3 - 2% / year thereafter.

ASHRAE studies show performance is typically degraded by 30% - 40% due to the buildup of lubricants on internal surfaces.

Some manufacturers attempt to control migrating oil with the use of mechanical devices such as

separators, skimmers, drums, heat sources, suction risers, traps, and pumps. According to ASHRAE’s Handbook, these high-tech designs are not efficient enough to prevent the oil from travelling through the system and subsequently insulating the inside of the coil tubes.

This thermal transfer efficiency loss can only be resolved by MaxR.

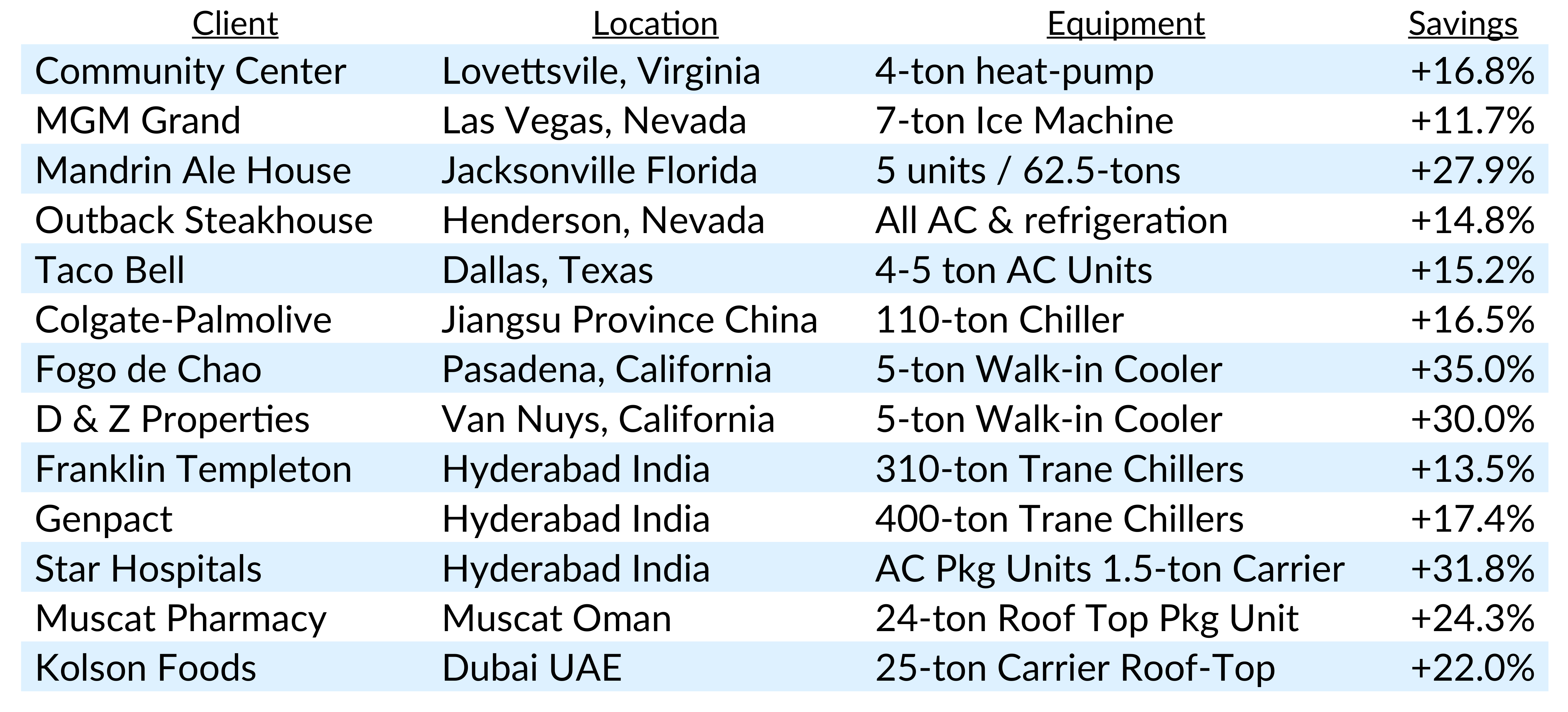

Proven Technology - MaxR has been in use for over 20 years in over 10,000 individual applications across 35 different countries.

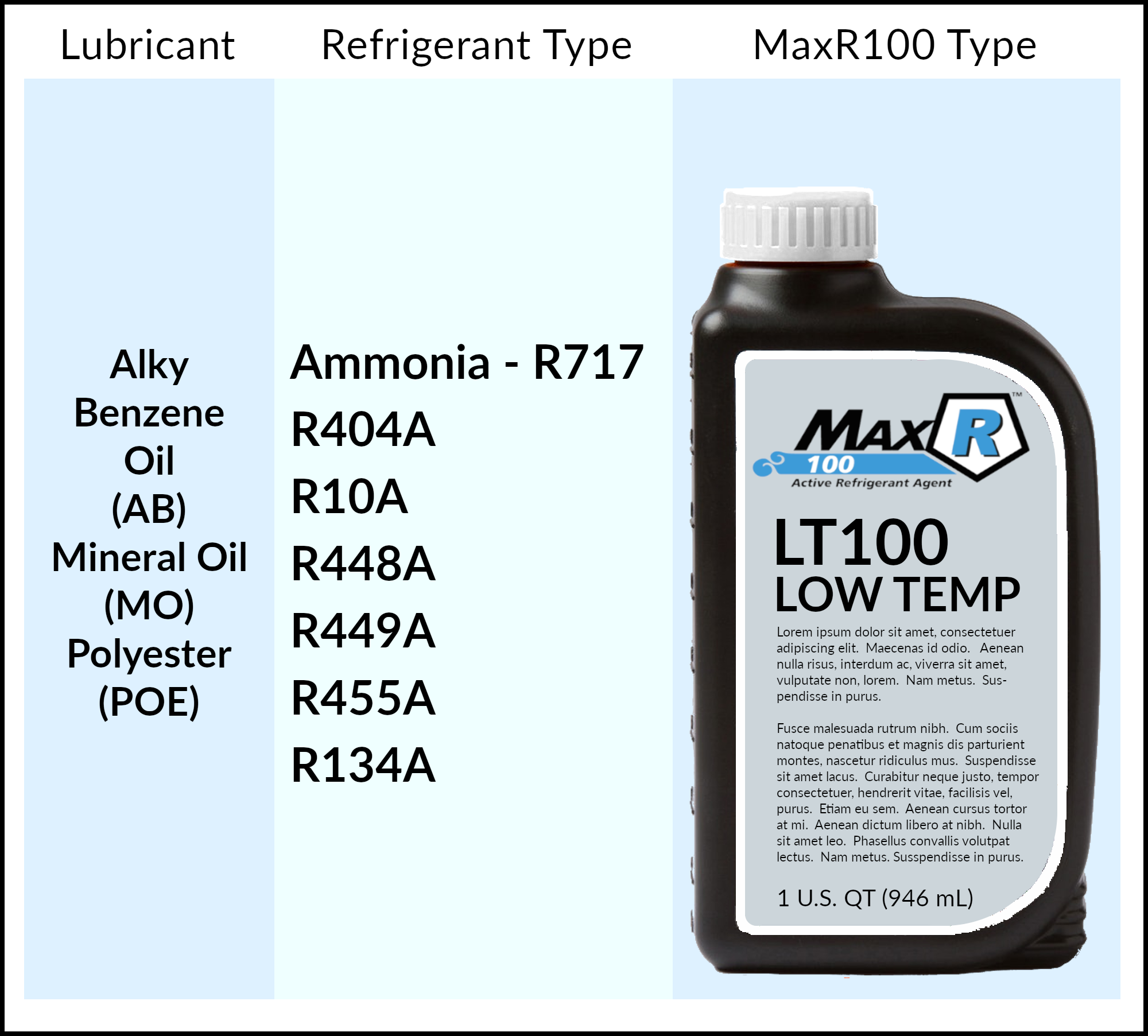

MaxR is blended for the specific combination of lubricant oil and refrigerant. This prevents damage to system seals, gaskets and valves and ensures maximum effectiveness, performance and safety.

We wrote the book

on solving HVAC oil fouling.

MaxR

Technical Description

Independent Test Results

164 Pages, English, 8.5 x 0.4 x 11 inches, ISBN 979-8870226491

ASHRAE - The American Society of Heating, Refrigerating and Air-Conditioning Engineers is an American professional association seeking to advance heating, ventilation, air conditioning and refrigeration systems design and construction. ASHRAE has more than 57,000 members in more than 132 countries worldwide.

Intertek (www.intertek.com) is a 130 year old quality assurance company with more than 46,000 employees in 1,000 locations in over 100 countries. They provide expertise to ensure that products meet quality, health, environmental, safety, and social accountability standards for virtually any market around the world. Intertek holds extensive global accreditations, recognitions, and has extensive expertise in overcoming regulatory, market and supply chain barriers.